OEE² -speed up your efficiency

Efficiency increase & problem solving in production

Companies know the situation: machines and plants are available, qualified employees are ready, yet the planned delivery dates and quantities are not met. Customers become increasingly dissatisfied, sales targets are missed and contractual penalties loom. We are familiar with such threats from production start-ups and new manufacturing processes. But they also occur from time to time in processes that are supposedly well established. With our OEE² system we approach challenges in production pragmatically. We identify the causes of problems and implement the necessary improvement and remedial measures together with our customers' employees.

-

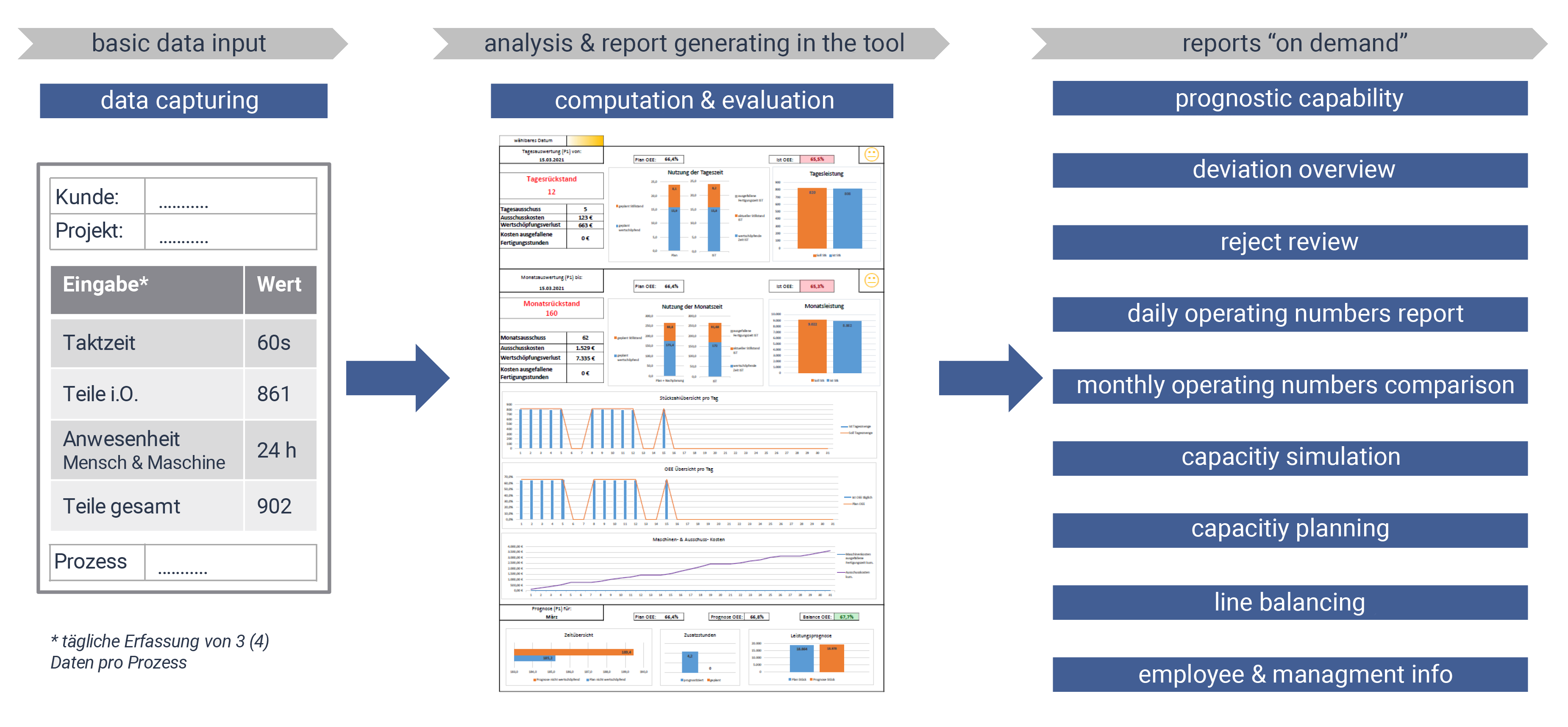

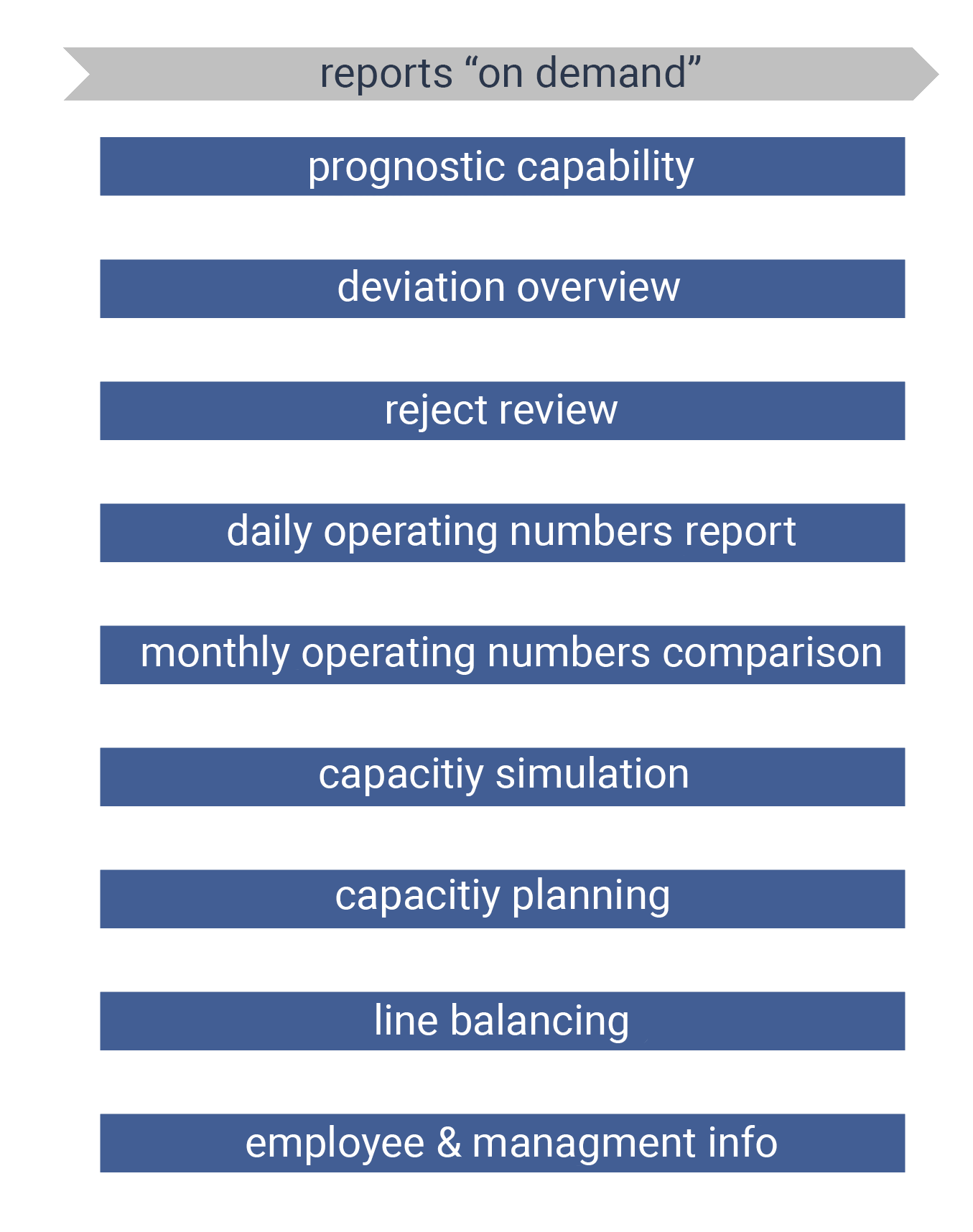

calculation & visualization tool

- analysis & prognosis tool

- task objective & decision support

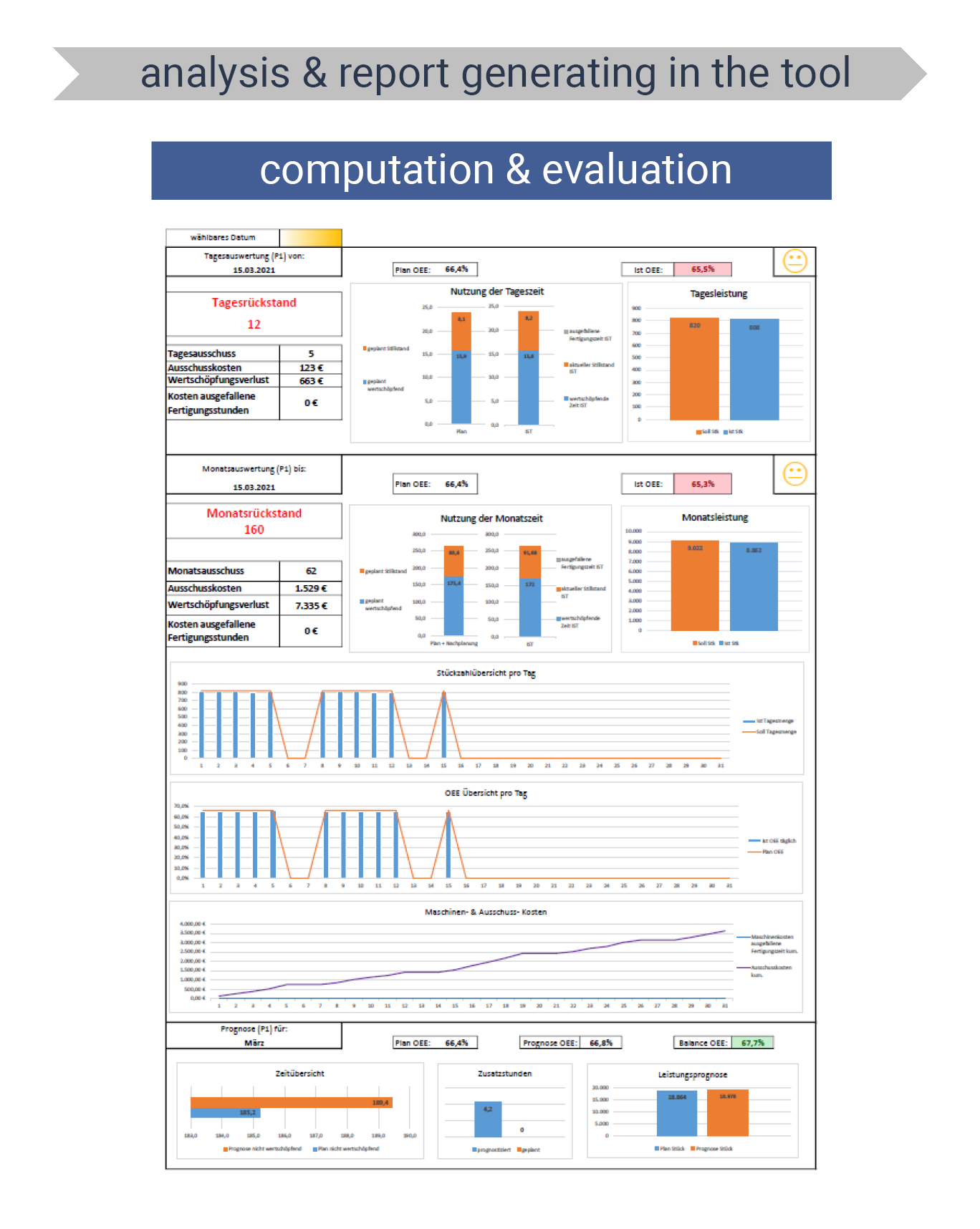

With our OEE² calculation and forecasting tools, we analyze relevant data quickly, efficiently and on a daily basis. This enables us to provide accurate forecasts of production targets. In the event of impending deviations, relevant activities are initiated promptly and in a problem-oriented manner. Our reports provide you, the user, with information on conspicuous production stages and processes. The procedure for achieving efficiency goals is optimally supported. Decision-makers and implementers are informed about significant deviations quickly and on a daily basis.

Employees are an important factor in efficient production. We have made it our task to involve employees and to draw a common picture of goals. Based on the common commitment to achieve the goals, the employees are informed about the current status on a daily basis. We ensure motivation and commitment by improving step by step as a team, developing and building knowledge, raising potentials and sustainably improving the added value in production.

With our OEE² system we approach challenges in production pragmatically. We identify the causes of problems and implement the necessary improvement and remedial measures together with our customers' employees.

Did you know that in a month with 20 working days (with 30 calendar days) and a plant efficiency of 65%, your plants stand still for about 355 hours or at least do not add value? No?! Our OEE² system gives you the opportunity to identify problem areas, eliminate causes, sensitise your employees regarding goals and significantly increase the added value of your production with a variety of individually customisable reporting, analysis and forecasting tools.

With OEE² you have a tool at hand that monitors your production in terms of quantities, OEE, rejects, added value and many other key figures promptly and at short notice. Keep an eye on your profitability at all times.

The forecast enables you to determine at the beginning of the month whether delivery promises will be kept and which scrap costs or value-added losses will occur. The integrated simulation option (WHAT-IF scenarios) allows you to plan possible increases in quantities or changes in working hours and view the results before they are included in the production plan and possibly lead to critical situations.

Daily information for management and production staff provides a better understanding of production, shows trends, increases employee satisfaction and thus the effectiveness of the entire production. A wide variety of problem-oriented reports that can be customised according to your needs directly involve the employees.

With a maximum of 4 data per process, machine or plant per day, we keep the effort as low as possible, but still show the full potential for efficiency improvement. You save yourself from: data chaos, fine-tuning, searching for old data and information backlogs.

Did you know that in a month with 20 working days (with 30 calendar days) and a plant efficiency of 65%, your plants stand still for about 355 hours or at least do not add value? No?! Our OEE² system gives you the opportunity to identify problem areas, eliminate causes, sensitise your employees regarding goals and significantly increase the added value of your production with a variety of individually customisable reporting, analysis and forecasting tools.

With OEE² you have a tool at hand that monitors your production in terms of quantities, OEE, rejects, added value and many other key figures promptly and at short notice. Keep an eye on your profitability at all times.

The forecast enables you to determine at the beginning of the month whether delivery promises will be kept and which scrap costs or value-added losses will occur. The integrated simulation option (WHAT-IF scenarios) allows you to plan possible increases in quantities or changes in working hours and view the results before they are included in the production plan and possibly lead to critical situations.

Daily information for management and production staff provides a better understanding of production, shows trends, increases employee satisfaction and thus the effectiveness of the entire production. A wide variety of problem-oriented reports that can be customised according to your needs directly involve the employees.

With a maximum of 4 data per process, machine or plant per day, we keep the effort as low as possible, but still show the full potential for efficiency improvement. You save yourself from: data chaos, fine-tuning, searching for old data and information backlogs.

English

English  Deutsch

Deutsch